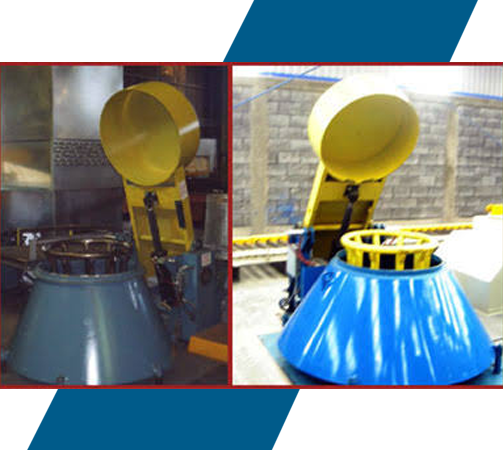

At Radadia Engineering, we revolutionize metal protection, taking galvanizing beyond limits." With our specialized spin galvanizing plant specially designed for your small, threaded, and precision-engineered components with high-speed centrifugal galvanizing for uniform and controlled zinc deposition. Breaking the limits of conventional galvanizing this advanced technique ensures a smooth, uniform zinc coating without excess buildup, preserving the functionality of fasteners, bolts, nuts, washers, and other intricate metal parts.

Uniform Zinc Coating – Prevents excess buildup on threads and small parts.

Corrosion & Rust Resistance – decades of protection against moisture, chemicals, and extreme environments.

Improved Thread Fit – Ensures bolts, nuts, and fasteners maintain proper functionality.

Durability & Strength – Enhances the lifespan of critical components.

Eco-Friendly Process – Uses recyclable zinc with minimal waste.