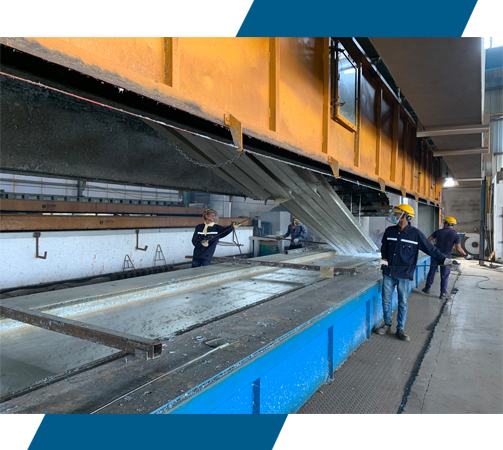

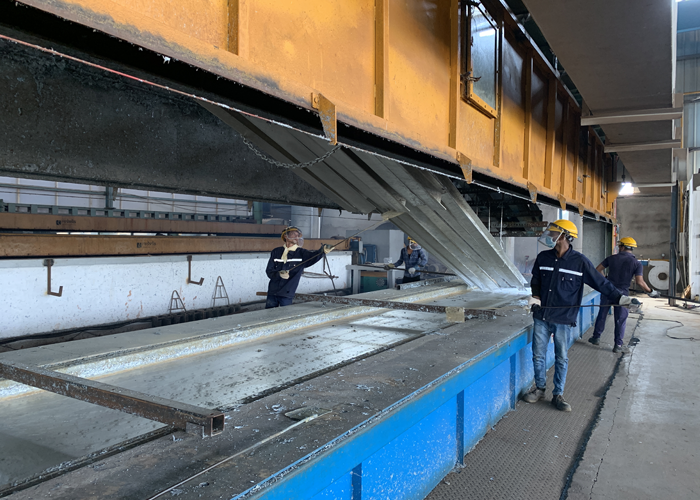

Galvanizing is a well-executed process of protecting steel and iron from corrosion by covering their structure with durable zinc coating. At Radadia Engineering, we offer galvanizing solutions that increase the shelf life of metal structures. Our advanced hot-dip galvanizing plants shields the metal from rust and corrosion, turning them into enduring, weatherproof, and maintenance-free structures, creating picture-perfect implementations for towering infrastructure, industrial machinery, or everyday utility products, our galvanizing solutions deliver strength, sustainability, and lasting brilliance.

Structural Steel – Beams, columns, and frameworks for buildings and bridges

Industrial Equipment – Pipes, tanks, and machinery parts for long-term durability

Automobile & Transportation – Truck bodies, trailers, and railway components

Agricultural & Utility Products – Fencing, poles, and irrigation equipment