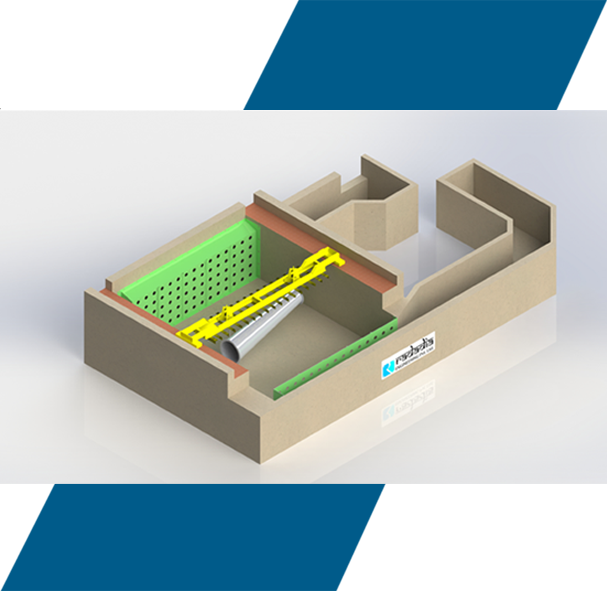

Heat resistant chain conveyor system

Covers and Steel Ducts for blowing air

Insulation: Rock wool

Paint: Special/Sand blasting

High capacity circulation fans

PLC Control Panel with precise temperature control

Dual (customized) push button stations for operator

Insulated covered Sliding Doors with power drives

Simplified Heavy Duty Construction

Reduces zinc consumption by reducing splash and dross

Reduces dip time

Improves quality of galvanizing

Specifically designed for the demanding galvanizing operation