started its journey, with a core experience of 40 Years in its inheritance, to become pioneer leading name serving the Galvanizing world. We are engaged in engineering, manufacturing, supplies and services of complete Hot Dip Galvanizing plant & equipment.

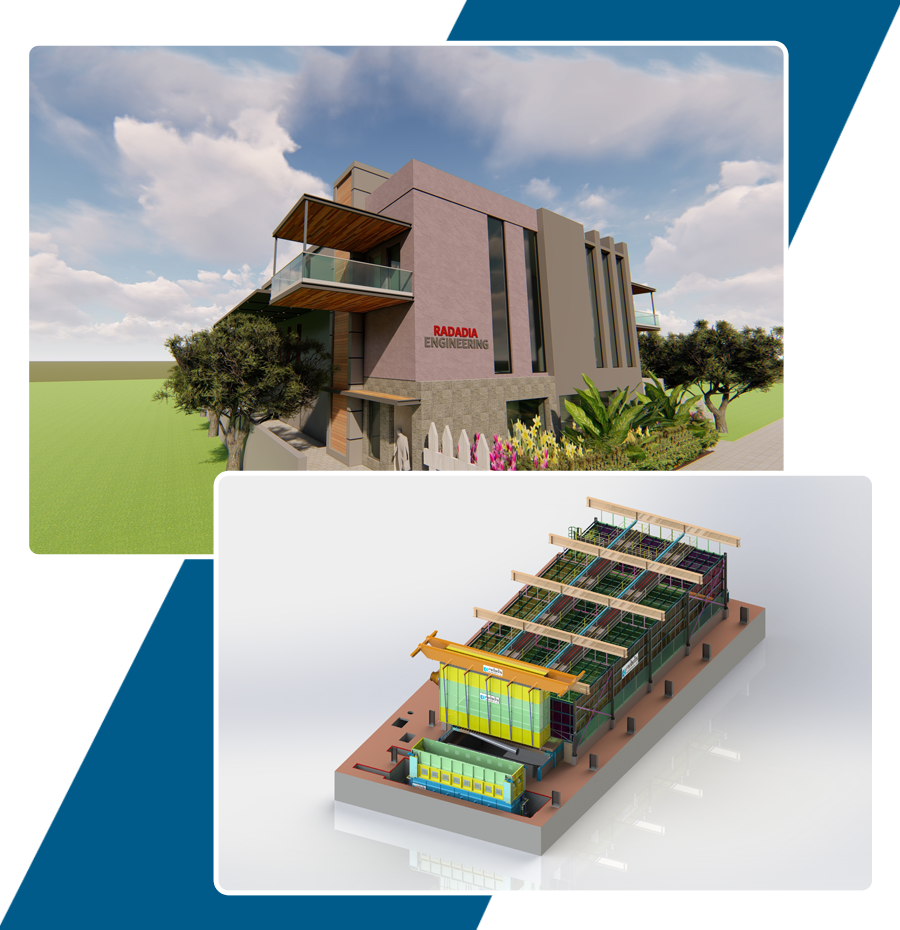

The company's facility is equipped with state of the art infrastructure, in house end to end production facility, research center and a highly skilled workforce to handle the multiple projects in parallel. REPL teams continuously put efforts to make a value for money offering a one spot under the roof solution for all Galvanizing requirements. We practice here for the working hand in hand with clients project team and management exhibiting a spirit towards creating the fastest payback & long term value for our valued clients.

To become the most reliable name in the Galvanizing World by providing the Best Designs, Futuristic Technology, Excellent Quality and Cost Effective Solutions.

To become the most employee friendly equal opportunity company with excellent growth possibilities in the segment.

To build lifelong relations with our clients assuring them the competitive edge in the market & facilitating them the lowest per unit production cost modules.

Our continuous innovation program for consistent technology, features and cost efficiency processes improvements is "never ending"

We are committed to comply with the most exacting customer needs and provide satisfaction through prompt supply of rightly engineered products delivering the best quality at most economic price.

The company is located near Ahmedabad in green city Gandhinagar, Gujarat.

We have established a high-tech infrastructure unit which is laced with all the advanced equipment and tools to manufacture and develop the exhibited product range complying the global standards meeting the client's. customized requirements.

The closely tracked end to end control system facilitates and the all norms compliant operations assure the best industry practices and quality business standards.

Radadia Engineering extends the experience of above 40 years in running the big capacity manufacturing plants, consulting 1 million MT annual capacities for several large successful completion, serving them Turnkey handover, Project consulting & Turnaround of loss making units within INDIA itself, besides working on several overseas projects

At Radadia Engineering we supply hot dip galvanizing plants & equipment, do design & engineering, manufacturing, turnkey and end to end consulting along with the following.