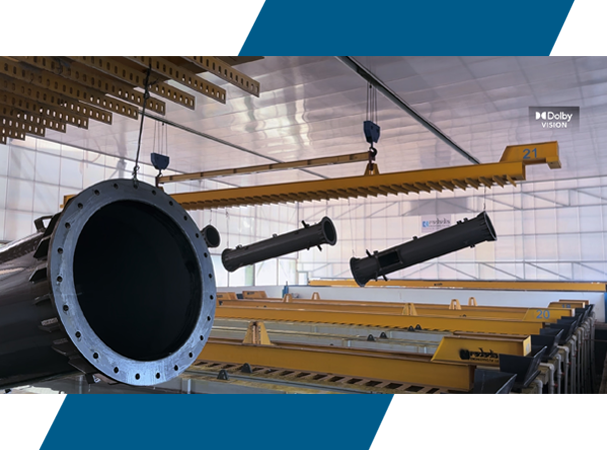

At Radadia Engineering we specialize in providing a Fully Enclosed Encapsulated Pre-treatment Room which offers a modern facility dedicated to delivering uniform conditions that support material pre-treatment steps before coating operations, galvanizing procedures, and paint application procedures. Our perfectly designed room enclosure provides contamination prevention which ensures top-quality outcomes.

REPL has successfully delivered encapsulation solutions for a plant furnace with a capacity of 1000 MTs and is now executing encapsulation for Asia's largest plant with a 1200 MT capacity which demonstrates our capability in handling large scale projects.