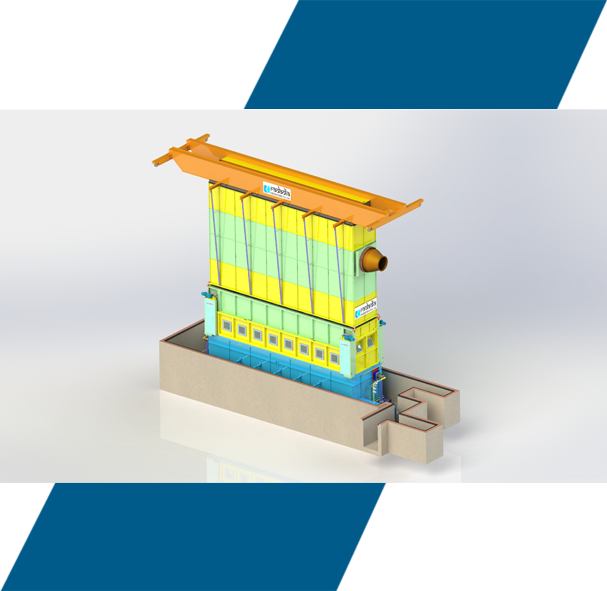

Hot dip galvanizing process emits sub-micron size moist air hygroscopic particulate. In other way to say that when steel material is dipped in to the molten zinc, very fine particles of Zinc Oxide are generated with Ammonium Chloride. REPL extraction and scrubbing systems are highly effective for an effective extracting of these fumes.